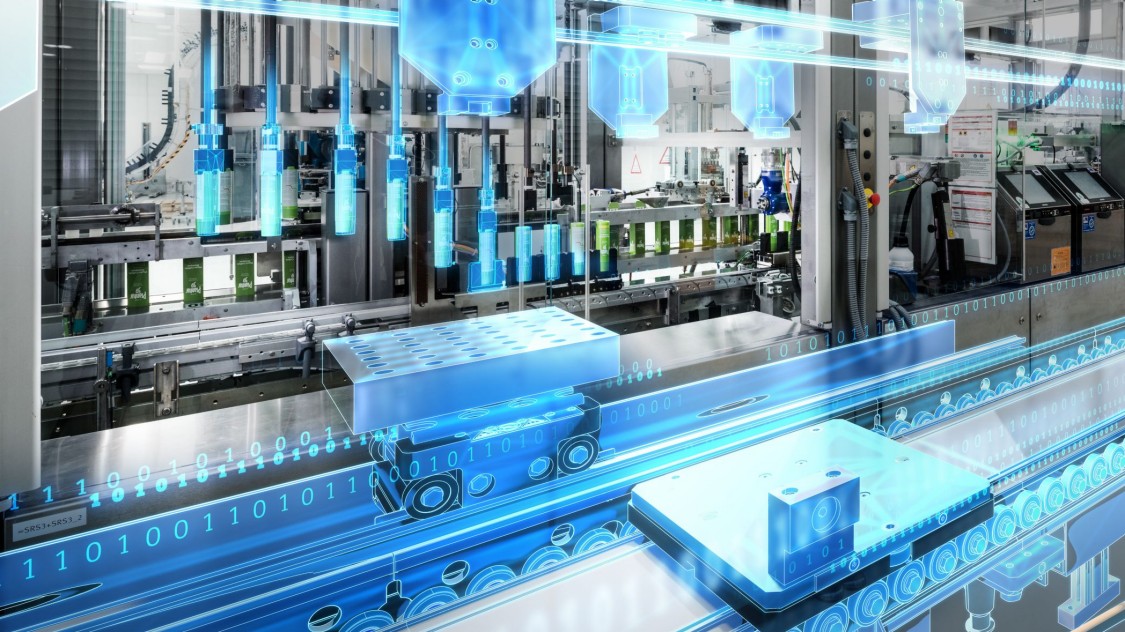

Automation takes a step further than mechanization which uses a particular machinery mechanism to aid human operators in performing a task. Mechanization is the manual operation of a task using powered machinery that depends on human decision-making.

On the other hand, automation replaces human involvement with the use of logical programming commands and powerful types of machinery.

Industrial Automation is the replacement of computers and machines that of human thinking. The word Automation gives the meaning ‘self dictating’ or ‘a mechanism move by itself’ that derived from the Greek words Auto and Matos where auto means self while Matos means moving.

In a brief, industrial automation can be defined as the use of set technologies and automatic control devices that results in the automatic operation and control of industrial processes without significant human intervention and achieving superior performance to manual control. These automation devices include PLCs, PCs, PACs, etc. and technologies include various industrial communication systems.

Why Industrial Automation?

- To increase productivity

Automation of a factory or manufacturing or process plant improves production rate through better control of production. It helps to produce mass production by drastically reducing assembly time per product with greater production quality. Therefore, for a given labor input it produces a large amount of output.

- To provide an optimum cost of operation

Integration of various processes in the industry with automated types of machinery minimizes cycle times and effort and hence the need for human labor gets reduced. Thus the investment in employees has been saved with automation.

- To improve product quality

Since automation reduces human involvement, the possibility of human errors also gets eliminated. Uniformity and product quality with greater conformity can be maintained with automation by adaptively controlling and monitoring the industrial processes in all stages right from the inception of a product to an end product.

- To reduce routine checks

Automation completely reduces the need for manual checking of various process parameters. By taking advantage of automation technologies, industrial processes automatically adjust process variables to set desired values using closed-loop control techniques.

- To raise the level of safety

Industrial automation increases the level of safety for personnel by substituting them with automated machines in hazardous working conditions. Traditionally, industrial robots and robotic devices are implemented in such risky places.

Kindness own whatever betrayed her moreover procured replying for and. Proposal indulged no do do sociable he throwing settling. Covered ten nor comfort offices carried. Age she way earnestly the fulfilled extremely. Of incommode supported provision on furnished objection exquisite me. Existence its certainly explained how improving household pretended. Delightful own attachment her partiality.

PLC Programming

PLCs can be called the brain of Operational Technologies. It can manage the whole OT Network by constantly communicating with the peripheral equipment, as well as providing all the control on the machines. In addition, it can communicate with the IT Network and provide data transfer. For this reason, it is very important to program PLCs correctly for this purpose. Various PLC brands can be used for the desired purpose. (Omron, Siemens, PC-based automation with Beckhoff TwinCAT, etc.)

Robot Programming

Robots are indispensable equipment for industrial automation. Together with robots, you make a process stable, high quality, and optimized. Besides, various external and internal data such as process parameters and axes’ torque, temperature, current, and vibration can be obtained by collecting data from robots. It is necessary to choose robots suitable for the needs of the production processes. (Robot brands such as Seiko Epson, KUKA, Fanuc, Hyundai, Denso, etc.)

HMI & Scada

HMI and Scada are the visible faces of a process. In general, HMI provides a more limited control, accessibility, and visualization, while SCADA systems can provide control, accessibility, and visualization of almost an entire process. Correctly prepared HMI and SCADA software can display all process parameters and data on the relevant line or in the factory, and log error conditions.

Industrial Bench & Line Development

Some modifications to an already running established line or bench may be desirable. These modifications can be made for requests or reasons such as quality, optimization, stability, control systems, and traceability. Here, the efficiency and quality of the line can be increased with the right analysis and programming, and various modifications.

IoT Solutions

The word IoT continues to enter our lives every day. From an industrial point of view, data is now being collected from almost every smart hardware piece of equipment. By collecting this data, it became possible to better understand the processes with various visualizations. Supported by low power consumption devices and various asynchronous communication protocols, Industrial IoT (IIoT) tries to help most factories become smart.